Any seal. Any time. Anywhere.

Materials

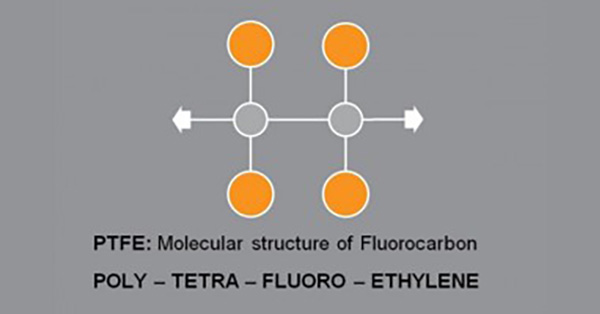

PTFE – Polytetrafluoroethylene

Polytetrafluoroethylene (PTFE) is the high-molecular-weight polymer of tetrafluoroethene. It is a thermosetting material with no melting point that is processed through sintering. PTFE offers a number of interesting features, including:

- Total chemical inertia, making it resistant to almost all chemicals;

- Extremely low friction coefficient – currently the lowest among industrial products;

- Complete insolubility in water and any organic solvent

- Excellent dielectric properties;

- Outstanding fire resistance properties, i.e. no flame propagation.

PTFE is used for a variety of applications in the industrial, food, electric and chemical fields. In the hydraulic-pneumatic sector it is used to produce seals and wear strips. Due to its low modulus of elasticity, it is often combined with high memory elastomeric parts or metal springs, to add elasticity/energising properties.

PTFE is available in virgin or filled with different additives in different percentages. Common fillers are molybdenum disulphide, glass, carbon, graphite and bronze, or combinations of each.

Prefix Code:- TF

Hardness:- 55 ± 3 duro shore D

Colour:- White

Temperature Range:- -200ºC to +260ºC

Prefix Code:- B

Hardness:- 60 ± 3 duro shore D

Colour:- Bronze/Brown

Temperature Range:- -200ºC to +260ºC